|

September 30, 2022: Moose Home Processing (37 Photos)

The beautiful bull moose I harvested on the 17th has been hanging in the cooler now approximately two weeks, so today Bassan and I started the process of cutting up/deboning the quarters. I converted my garage aka Area51 to a meat processing facility first by thoroughly cleaning all surfaces particularly my stainless steel bench and thoroughly mopping the floor. The bike and Argo have both been stored in the trailer since we got back from moose hunting 2 weeks ago and all other containers of fuel etc are empty and well sealed.

In this pic, the floor appears dirty but its just the epoxy coating I put in on 2014 wearing through after 8 years of service and many many projects.

We retrieved the quarters from the moose cooler 2 at a time and systematically worked our way through each one. Bassan separated out and removed the roasts one by one, while I trimmed down the bones and scrappy bits creating a small tub (black) to be discarded and a large tub of trimmings to be ground. In our experience, trimming out the grizzle, tendons and moose fat makes for a way better tasting & texture of ground meat.

Some people enjoy and use moose fat, personally I find it sour as does the rest of our crew, we trim it out during our processing.

Meanwhile I had the Pitboss fired up and a pork shoulder smoking away to make some epic pulled pork for our supper.

Today I seasoned the meat with Salt-Pepper-Garlic and Meat Church Honey Hog. My Meater+ let me monitor the progress from the garage without having to run back and forth.

The pulled pork came out amazing and was served with rendered juice from the 2nd half of the cook on the side, along with a selection of BBQ & Hot Sauces and French fries.

Work continued late into the evening but we got the last quarters done before midnight.

Saturday afternoon we picked up the full meat totes from the moose cooler and then began the process of grinding and bagging. I ran the meat grinder while Bassan weighed and bagged the meat in 2 & 5lb ziplock bags. My Kitchen Aid grinder attached to Sandra's 575watt mixer is still working very well!

Of course moose processing can't sensibly continue without a taste test!

On the menu today was chicken legs lightly seasoned with Suckle Busters Clucker Dust and grilled on the Pitboss.

With supper and ground meat complete, we began bagging up roasts. In the past we also used ziplock bags for roasts, but this year we decided to vacuum seal them to prevent freezer burn while in extended storage.

Running 2 machines at once really sped up the process as one machine was loaded up while the other one was sealing.

The last step was counting out and diving our harvest equally into 4 shares, one for each member of our hunting party. Some groups take a quarter each choosing front or rear, we prefer to do it this way as it's perfectly even amongst the crew.

One final small roast was also sliced thin and pan fried as a taste test. It was absolutely fantastic, very tender and tasty! This beautiful bull moose dressed in at 430 lbs when we put it in the cooler, after drying down for 2 weeks, then trimming and deboning we cleared 276lbs of meat which includes all roasts and ground meat!

The following day I threw a couple blocks of Old Cheddar Cheese on the Pitboss to cold smoke for a future project. To do this I DID NOT turn on the pellet smoker, the lowest setting on the pit boss is too hot and will sweat and probably melt the cheese. Instead I simply lit my Lumberjack smoker box filled with apple wood pellets and let that run on its own.

It smoldered away perfect never getting the unit over 90F and burned for about 3 hours. Once finished, I vacuum sealed the 2 blocks and let them rest in the fridge for 2 weeks to mellow.

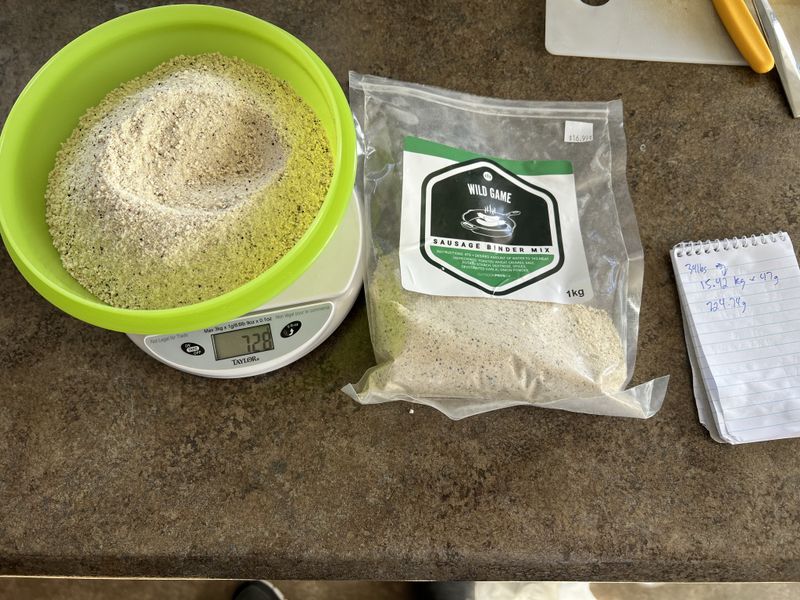

Today I started making my very favourite moose sausages, the recipe was 12lbs of Costco lean ground pork, 17lbs of ground moose, a block and a half of my smoked cheddar cheese diced, and 10 Jalapeño peppers also diced seeds and all .

The final ingredient is Outdoor Pros Wild Game sausage flavouring which has a very pleasant salty/garlic/pepper flavour.

First I thoroughly hand mixed the two kinds of meat along with the Wild Game seasoning and 2 cups of water.

Before continuing I pan fried a sample to check if there was enough seasoning or too much. If the seasoning is too strong it will usually be very salty, to fix you can add a couple more bags of ground meat to the mix.

Happy with the taste, next I added the peppers & cheese and continued hand mixing to evenly distribute the epic ingredients.

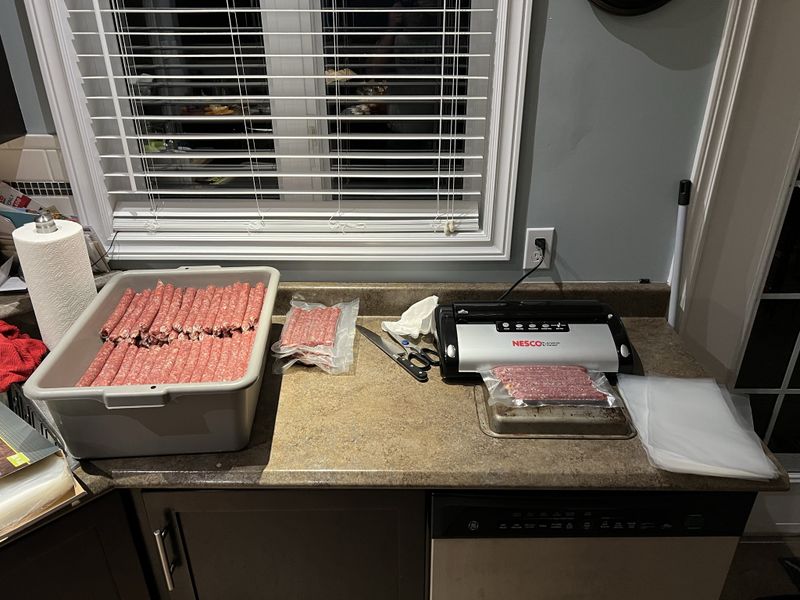

Now I was ready to stuff, today I used 23mm collagen casings swapping to larger 30mm at the end. To make sausages I highly recommend getting a proper manual sausage stuffer as it makes the job easy for one person and creates much more consistently stuffed casings. Also if using the attachment for a meat grinder, you will pulverize your cheese & peppers in the stuffing process, whereas a manual unit will not.

I like to twist and cut my links into even lengths usually 7" long.

The thicker sausages were cut a little shorter and are really nice on the BBQ.

The final step is vacuum packing which provides the best protection against freezer burn especially in the long term.

Now I'm all set for the winter meals & outdoor adventures with a suitable quantity of my absolute favourite sausages in stock. Stay tuned as later this fall I plan to make moose Snackin Sticks on the smoker, and possibly a batch of my homemade recipe hot Italian sausages as well!

Cheers, MIKE

Copyright © 2011 Michael Smith |